Dear Kelloists,

We’ve made big progress during the last 2 weeks on manufacturing preparation and electronics design. Here’s a roundup of what we’ve been working on.

New Microcontroller

As mentioned in our last update, last December we chose to change the brains of Kello to make them more powerful and future-proof.

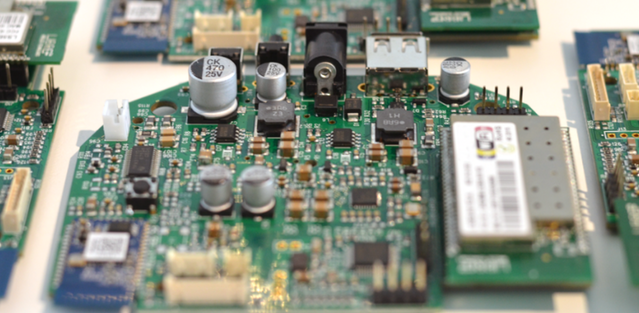

It took us a few weeks to redesign the whole mother board, and we just got the prototype of our motherboard with the new microcontroller: everything is working as expected.

The board with the new microcontroller

This means that we can keep chasing bugs and add features directly on the new motherboard.

Design for Manufacturing

Another big news: we just finished Design for Manufacturing! Our factory worked tirelessly to make the most effective design for Kello without changing its external appearance.

Kello isn’t an easy product. It has:

- a powerful speaker (that can creates all sorts of vibrations),

- a mechanical snooze button (that must be easily clickable without being flimsy),

- and a dozen of other mechanical constraints (LED screen, fabric cover, silicon buttons, light sensor…).

Each of these constraints is a design challenge that our engineers had to overcome. And the result is impressive: in 8 weeks, our mechanical engineers took our design to the next level.

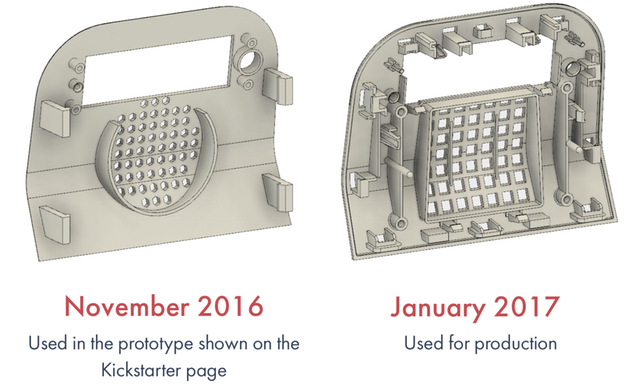

Here’s an example of the work done on the “front panel” part of Kello (viewed from behind and without its fabric cover).

The iterations we made during the last months will make for a more durable and higher quality product.

Now we can move towards one of the biggest steps in manufacturing a product: making the plastics injection molds.

Mass Manufacturing

Plastic Injection Molds

To mass manufacture Kello, we’re using the plastic injection technology: liquid plastic is injected with high pressure in big steels moulds.

These moulds basically are “negatives” of our plastic parts. They need to be carefully designed, then machined with high precision tools, and our factory just started this process.

Procurement

Additionally to the mold manufacturing kick off, last week we placed the order for the long lead time electronics components needed to manufacture a few thousands of Kellos. All parts should arrive in time for mass manufacturing.

Chinese New Year & Next Steps

On the manufacturing side, the next two weeks will be slow as China is on vacation. We’ll use this time to work on the Kello firmware and on the new version of our iOS and Android apps.